Taisei Co., Ltd. is a general contractor that manages large-scale construction work including skyscrapers, dams, bridges, tunnels and subways across Japan and overseas, while also participating in urban development and engineering. Taisei introduced LINE WORKS as a tool to communicate with employees leading construction work in large-scale sites all across Japan, and with its numerous business associates. We interviewed Sato from the Civil Engineering Headquarters, and Miyaji from the Yokohama Branch, to learn about the diverse methods of utilizing LINEWORKS in a construction site building a road shield tunnel, led by the Yokohama branch.

Please tell us about your business, roles, and responsibilities

Mr. Sato:

As the Director of Work Style Reform Division in the Civil Engineering Headquarters, I support boosting work efficiency and reforming the way we work in construction sites across Japan.

Mr. Miyaji:

I am the Operation Manager of the Yokohama Branch, and I’m in charge of project management on site for the road shield tunnel construction.

What challenges did you face in construction sites, and what was the decisive reason that drove your company to introduce LINE WORKS?

Mr. Miyaji:

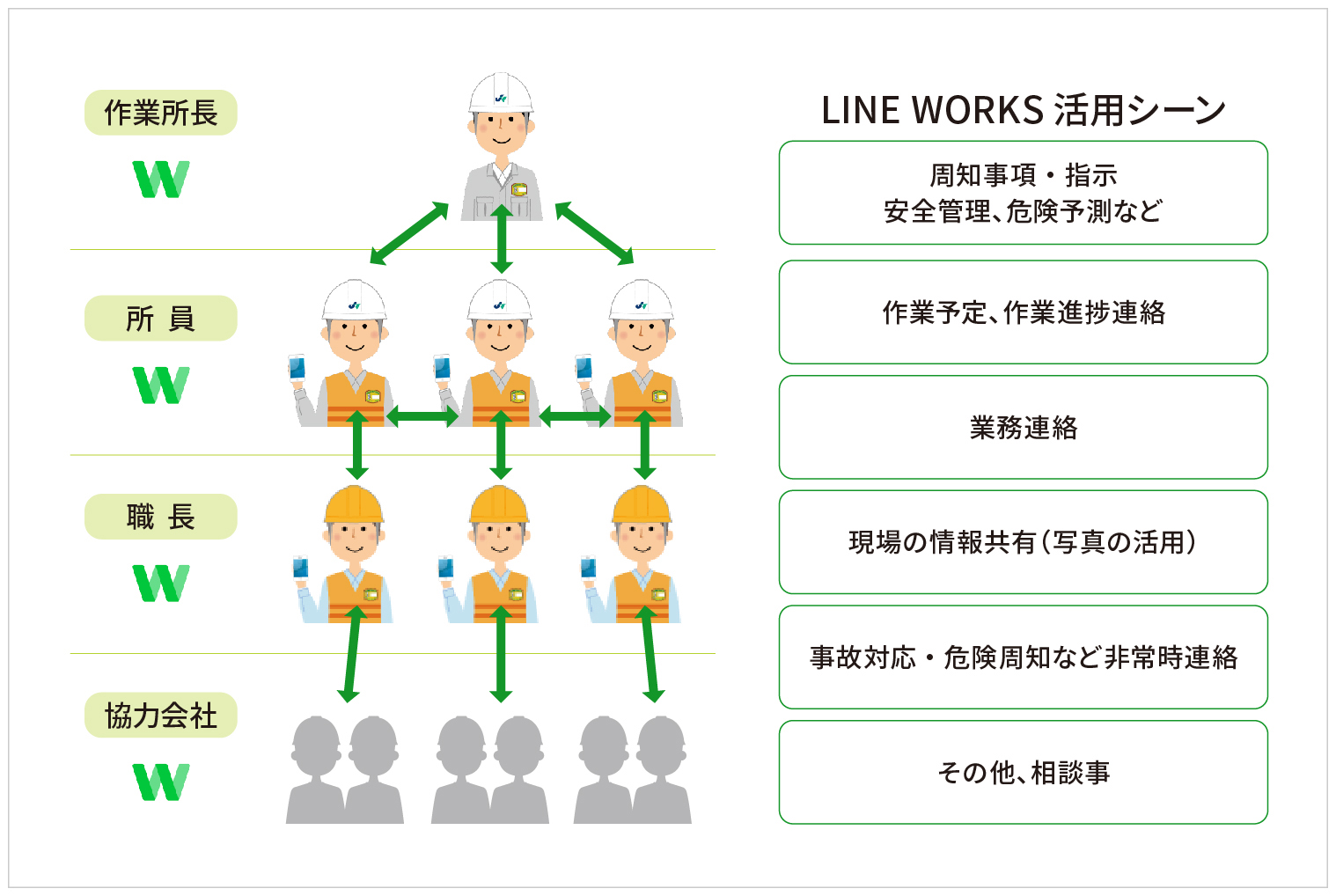

In constructing a shield tunnel that easily covers several kilometers in length, about 20 employees are stationed on site, and about 50 other contractors work on a site-by-site basis. As the operation manager, I am in charge of overall management—I check up with the people in charge to grasp the progress in field. However, I felt it quite cumbersome to check up on each individual through a phone call or an email, and again deliver the information to other employees. I thought we needed a safe and more convenient tool for communication.

Mr. Sato:

With the number of employees decreasing due to a shortage of workers, and with the recent situation of reducing overtime work and providing holiday leaves, the construction industry is striving to reform the way we work. In order to drive for the same results as before, we need to increase work efficiency to improve the overall productivity.

We thought that reducing the waste of time through seamless communication on site was absolutely necessary. Especially at construction sites, people working in remote locations have to collaborate very closely. So, after examining various communication tools, we concluded that LINE WORKS is the most suitable because of its easy-to-use interface and its renowned security equipped with a system that prevents information leakage. Up until now, 84 out of around 200 workshops in the Civil Engineering department of Taisei Co.,Ltd. have introduced LINE WORKS, and are utilizing it.

Do you have any tips for using LINE WORKS in construction sites?

group message room you are in

Mr. Miyaji:

Since various associate companies take part in construction sites, we used a design that can remind us of the work content for the message room icon. For sites where personnel change frequently depending on the progress of the project, we made a special rule that all workers use their face for the Contacts profile icon. This enabled our workforce to easily recognize which group message room they are in, and who is in it.

Mr. Sato:

Since radio waves cannot reach some spots inside the tunnel, we installed Wi-Fi to enable communication. Moreover, since it is quite inconvenient to type a long message with a phone in construction sites, we installed a shared PC that enables employees to log-in to their accounts in major locations in the field.

How exactly is LINE WORKS being used?

Mr. Miyaji:

Employees working in the field can now quickly report various issues with LINE WORKS instead of a call or an email. We can grasp the situation more clearly and vividly with attached photos and videos. Moreover, since we can now identify safety issues at a glance with a video, safety managers like myself no longer need to visit the scene in order to inform other employees of what we have learned and what to be careful of. It is almost like going on an online ‘safety patrol.’

a photo to report progression faster

the tension at the construction sites

As we can now deliver information through group message rooms at once, I can deliver the project’s progress to the employees or relevant personnel much faster than before. Thankfully, I no longer need to explain the project’s progress in detail during morning and evening assemblies when everyone gets together. Now day time workers transfer their duties to night time workers through LINE WORKS, instead of paper transition documents. LINE WORKS is easier to read than the paper document, and we can also check for the ‘read‘ notification. This has enabled employees to be clearer in the transition process. Furthermore, another big strength of LINE WORKS is that you can gather members and create message rooms to share information with only members who need them. Sparing the cost of delivering information to irrelevant workforce has contributed to improving work efficiency.

At sites where various companies work together, each company has to share where and what they are doing everyday with blueprints and progress schedules. Before, these documents were delivered in paper during morning assemblies; yet now, even employees who missed an assembly can access the information because we deliver them to everyone through attached files. It has even become possible to distinguish who has checked the information and who has not, so there is much less anxiety about whether the information is being delivered.

What changes did LINE WORKS bring to the field?

Mr. Sato:

Before, evening assemblies usually took around an hour, but now it only takes five to ten minutes. We estimated that this would enable each employee shorten about one working hour each day. Since one out of eight working hours can now be redistributed to the project, this led to an improvement in construction speed and quality, and a decrease in overtime costs. I believe that this is contributing greatly to the overall improvement in productivity.

Mr. Miyaji:

Sometimes scheduled projects suddenly undergo changes due to various circumstances. In these kinds of situations, an unexpected accident might occur if relevant information is not shared to every relevant employee fast and accurately. As we can now make immediate announcements about project schedule changes through LINE WORKS, it also helps strengthening safety measures in the field.

Which features other than Message is your company using?

Mr. Miyaji:

Up until now, we have announced the field schedule like safety inspections and meeting dates by writing them on a whiteboard, but now anyone can share their schedule anytime on their phone with the Calendar feature.

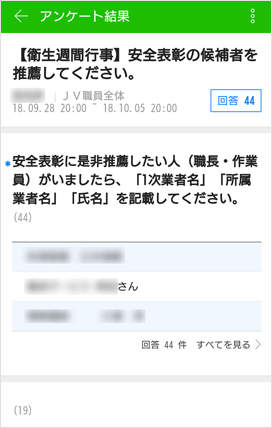

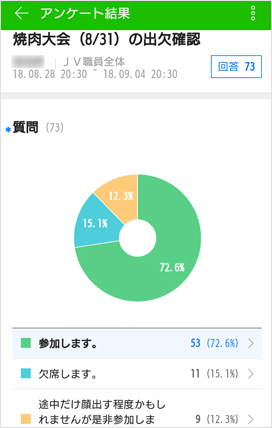

In addition, we are utilizing Form when nominating a candidate for safety awards or when checking attendance for social gatherings. We just send the information at once to everyone in the field (around 70 people), and in the blink of an eye we get replies back—it’s so convenient.

and collect information

organized into a chart

How do you plan to utilize LINE WORKS in the future?

Mr. Miyaji:

I would like to try its various features and further streamline the entire field communication, improving work efficiency and productivity.

Mr. Sato:

In order to utilize LINE WORKS more effectively, I believe that it is important for the headquarters to regularly exchange feedback with each work station, and listen to actual use cases and feedback. After hearing feedback, we will encourage employees to utilize LINE WORKS according to the size and characteristics of each field.

※ All details, affiliations, and positions specified were gathered at the time of interview.